Laser build-up printed circuit board

Overview

With the laser build-up structure, it becomes a printed wiring board that can be thinned and downsized.

Laser build-up type

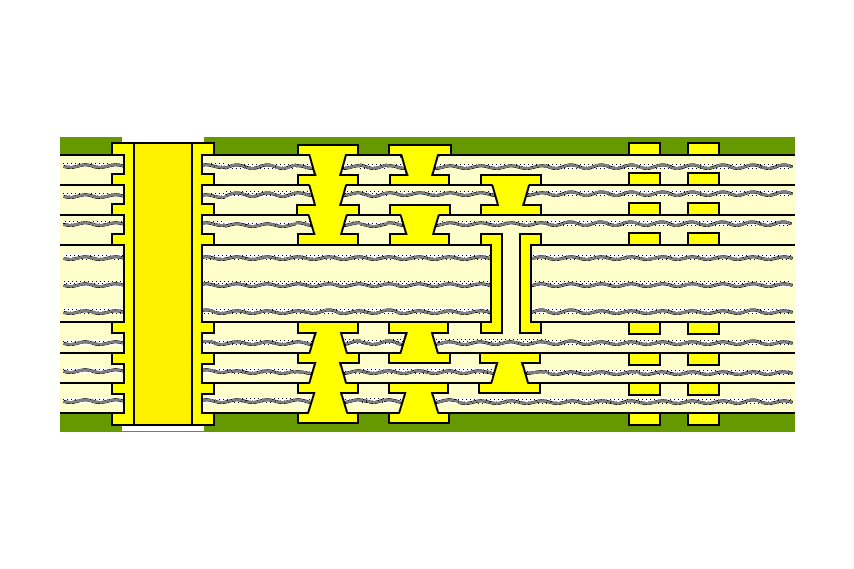

Stacker via structure

LVH 2-stage stacker connection

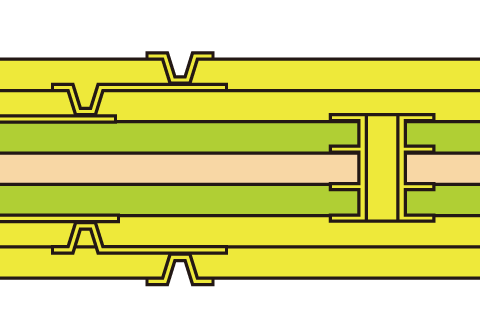

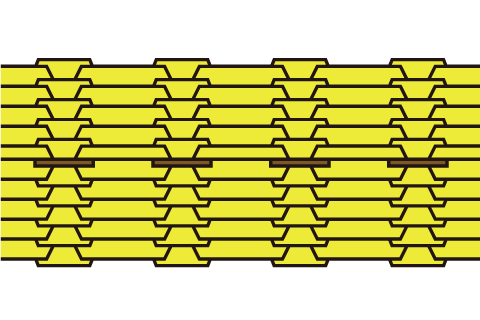

Stack via structure

5 steps just above the IVH

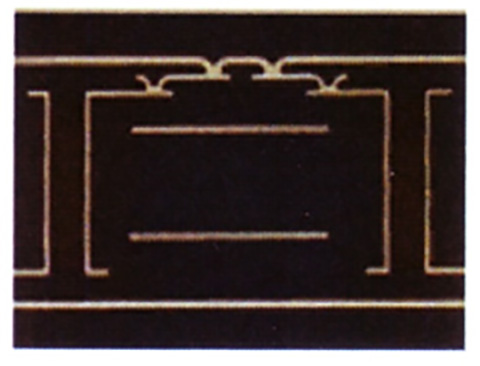

10-stage coreless connection

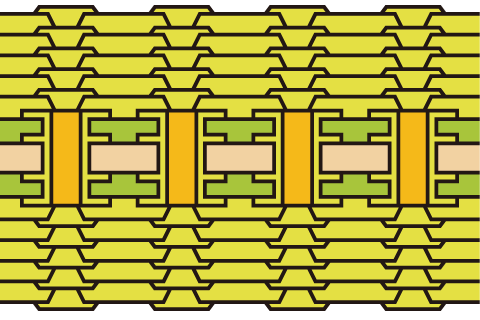

All-stage prepreg composition

- Features

-

It is possible to cope with thinning and miniaturization by wiring board using correlation connection technology by laser via.

With high density wiring, narrow pitch CSP can be mounted.

- Use

-

AV equipment · home appliances

amusement

Health · Medical

Industrial equipment · Lighting

On-board

- Stack-up

-

Multilayer

HDI

- Number of layers

-

4 layers and 6layers

Standard specification

| Items | Standard specification | ||

|---|---|---|---|

| External layer | Min. Conductor width | 0.075mm | |

| Min. Spacing of conductor | 0.075mm | ||

| Internal layer | Min. Conductor width | 0.1mm(0.075) | |

| Min. Spacing of conductor | 0.1mm(0.075) | ||

| Conductor thickness of external layer | 18µm | ||

| Plating thickness of through hole (Combination Type) | IVH | 15µm | |

| TH | 20µm | ||

| Via | Smallest land diameter of external layer | Laser-via | φ0.275(φ0.25) |

| TH | φ0.6 | ||

| Smallest land diameter of internal layer | Laser | φ0.275(φ0.25) | |

| TH | φ0.5 | ||

| Smallest hole diameter | IVH | φ0.2 | |

| TH | φ0.25 | ||

| Number of layer | 4. 6. 8, 10 | ||