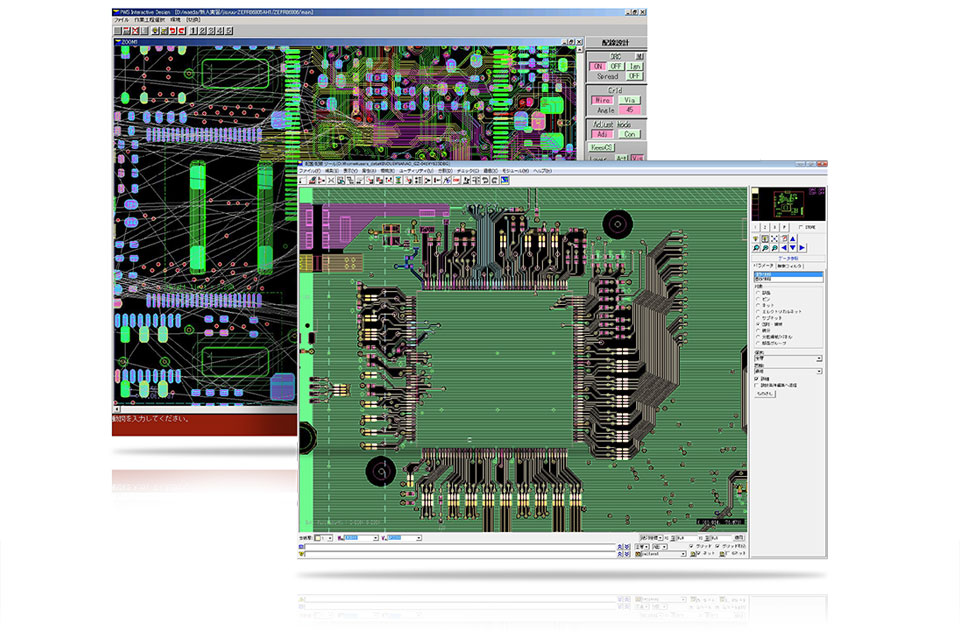

CAD Design

Provision of board design incorporating know-how of “manufacturing” by mass production manufacturer

Collaboration between design department and manufacturing department realizes total support from design to manufacture.

We deal with customer’s requests with a light footwork and are trusted by many customers.

We provide board design that is reliable, safe and easy to manufacture, corresponding to the design of a wide variety of boards from 2 layer to High multilayer board and from through hole to build-up board.

Feature

High quality design that included board manufacturing know-how unique to mass-production manufacturer.

- Establishment of the most suitable design specifications in consideration of quality, cost.

- Smooth transition from trial production to mass production.

Total service such as the price examination at the design stage, the VA suggestion.

- Examination of economic board size without waste.

Simulation at the design stage

(Reduction of the evaluation number of times with the trial product)

- Correspondence of the simulation in the highspeed transmission line.

Suggest a better conditions. - The measurement result of the board is fed back to the immediate design data.

Correspondence to short delivery date.

- We will respond with a flexible system matched it with schedule.

Flow of the design

Spec

Request

Design start

Design start

We confirm the specification of the design contents, we will judgment of the manufacturability and assemble the process untill board making.

Board Design (CAD)

Net making

Net making

Corresponds to the circuit and net of “CR-5000 SD” In addition,

we will correspond to various net-list.

Part registration

Part registration

We will manage it in library for exclusive use of the customer and correspond.

Outline making

Outline making

If you got DXF data with various drawing information, it can be imported directly to CAD and design time can be shortening is possible.

Part placement and pattern wiring/ Art work

Part placement and pattern wiring/Art work

The smooth board design system by the experienced designer.

We will correspond of design in accordance with customer needs.

(Design system closely tied to customers)

Simulation

Simulation(Transmission line analysis)

We will perform pre-simulation and post-simulation according to customer request.

Impedance control makes more realistic and accurate matching considering manufacturing conditions.

Verification

DRC

DRC(Rule Check)

In addition to checking the designing wiring rules, we will perform the rule check in each design condition.

Manufactur ability verification

Manufacturability verification(ADM)

It checks whether it violates the manufacturing specifications at the stage of CAD data,

it checks and corrects the error part promptly, and does not carry over the violation part to the next process.

Manufacture

Output

Output

After completion of approval process, we will shift to manufacturing immediately.

We will output metal-mask data necessary for part implementation, part coordinate data and a drawing necessary for a customer.

プリント配線板設計技能士

Skilled worker of printed circuit board design

Certified skilled worker(Grade 1 and Grade 2) are presence.

A skilled designer will provide a high level of quality.

CAD System

Printed circuit board design tool

- CR-5000 BoardDesiner

- CR-5000 PWS

- CR-8000 Design Force

- Altium Designer

- Cadence Allegro

Circuit design tool

- CR-5000 SystemDesigner

- CR-8000 Design Gateway

Waveform analysis/EMI measures tool

- CR5000 Lightning

- Hyper Lynx

DRC/Manufacturability check tool

- CR5000 ADM

(Including partner company)

Design achievement example

Automobile

- ECU(Engine control、Steering control、Feeding control)

- Onboard parts(Body control、Electronic unit、Air conditioning、Safety device)

- Onboard product(Navigation、Audio)

PC peripheral equipment

- (Memory card、Priter)

Industrial equipment

- (Industrial robot、High speed wireless communication、Image processing)